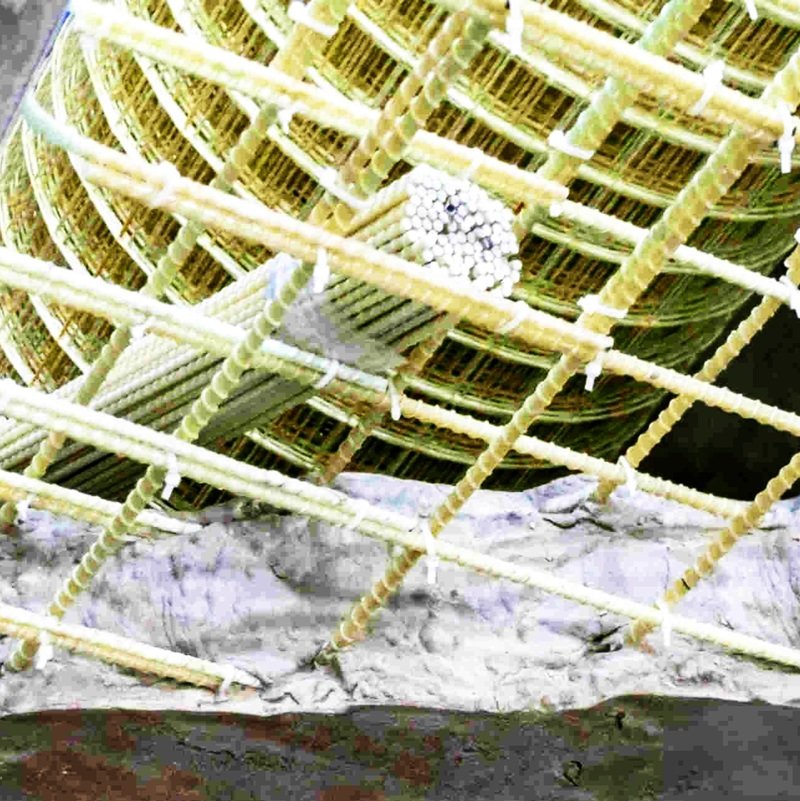

FRP Rebars, designed and manufactured to meet the stringent demands of modern industrial applications

What Are FRP Rebars?

RP Rebars are reinforcement bars made from a composite of fiberglass and resin, designed to provide a strong and durable alternative to traditional steel rebar. Unlike steel, FRP rebars are non-corrosive, lightweight, and boast a high tensile strength, making them particularly suitable for environments exposed to harsh chemicals and moisture.

Design and Engineering

At ASK Enterprises, our FRP Rebars are crafted using advanced pultrusion techniques, ensuring consistent quality and performance. Key design features include:

- High Tensile Strength: Engineered to deliver superior strength, FRP rebars can withstand significant loads without compromising structural integrity.

- Corrosion Resistance: The fiberglass and resin composition ensures that the rebars are highly resistant to chemical and environmental corrosion.

- Lightweight Construction: FRP rebars are significantly lighter than steel, making them easier to handle and install without sacrificing strength.

Applications

Our FRP Rebars are ideal for a wide range of industrial and construction applications, including:

- Bridges and Infrastructure: Providing durable reinforcement for bridge decks, piers, and other infrastructure projects exposed to de-icing salts and harsh weather.

- Marine Structures: Offering corrosion-resistant reinforcement for docks, seawalls, and other marine applications.

- Industrial Flooring: Ensuring strong and durable reinforcement for factory floors and other heavy-duty industrial settings.

- Water Treatment Facilities: Providing long-lasting reinforcement for concrete structures in wastewater and water treatment plants.

Key Benefits

Superior Corrosion Resistance

- Benefit: FRP rebars are inherently resistant to corrosion from chemicals, moisture, and environmental factors, unlike traditional steel rebars.

- Advantage: This resistance extends the lifespan of the reinforced structures, reducing maintenance and replacement costs.

High Strength and Durability

- Benefit: With excellent tensile strength, FRP rebars provide robust reinforcement that enhances the structural integrity of concrete constructions.

- Advantage: Structures reinforced with FRP rebars can withstand higher loads and stress, ensuring long-term reliability.

Lightweight and Easy Handling

- Benefit: FRP rebars are much lighter than steel, making them easier to transport, handle, and install.

- Advantage: This reduces labor costs and installation time, contributing to overall project efficiency and cost savings.

Non-Conductive Properties

- Benefit: FRP rebars do not conduct electricity, making them ideal for use in applications where electrical insulation is crucial.

- Advantage: This property enhances safety and performance in electrical and electronic infrastructure projects.

Environmentally Friendly

- Benefit: The production of FRP rebars involves fewer emissions and energy consumption compared to steel.

- Advantage: Using FRP rebars contributes to more sustainable construction practices, aligning with green building initiatives.

Enhance the durability and performance of your concrete structures with ASK Enterprises' advanced FRP Rebars

Contact us today to discuss your requirements and discover how our innovative solutions can benefit your projects