ASK Enterprises, leading Chemical Process Tank manufacturer

FRP 7 Tank Process Tanks – Reliable Solutions for Chemical & Surface Treatment Industries

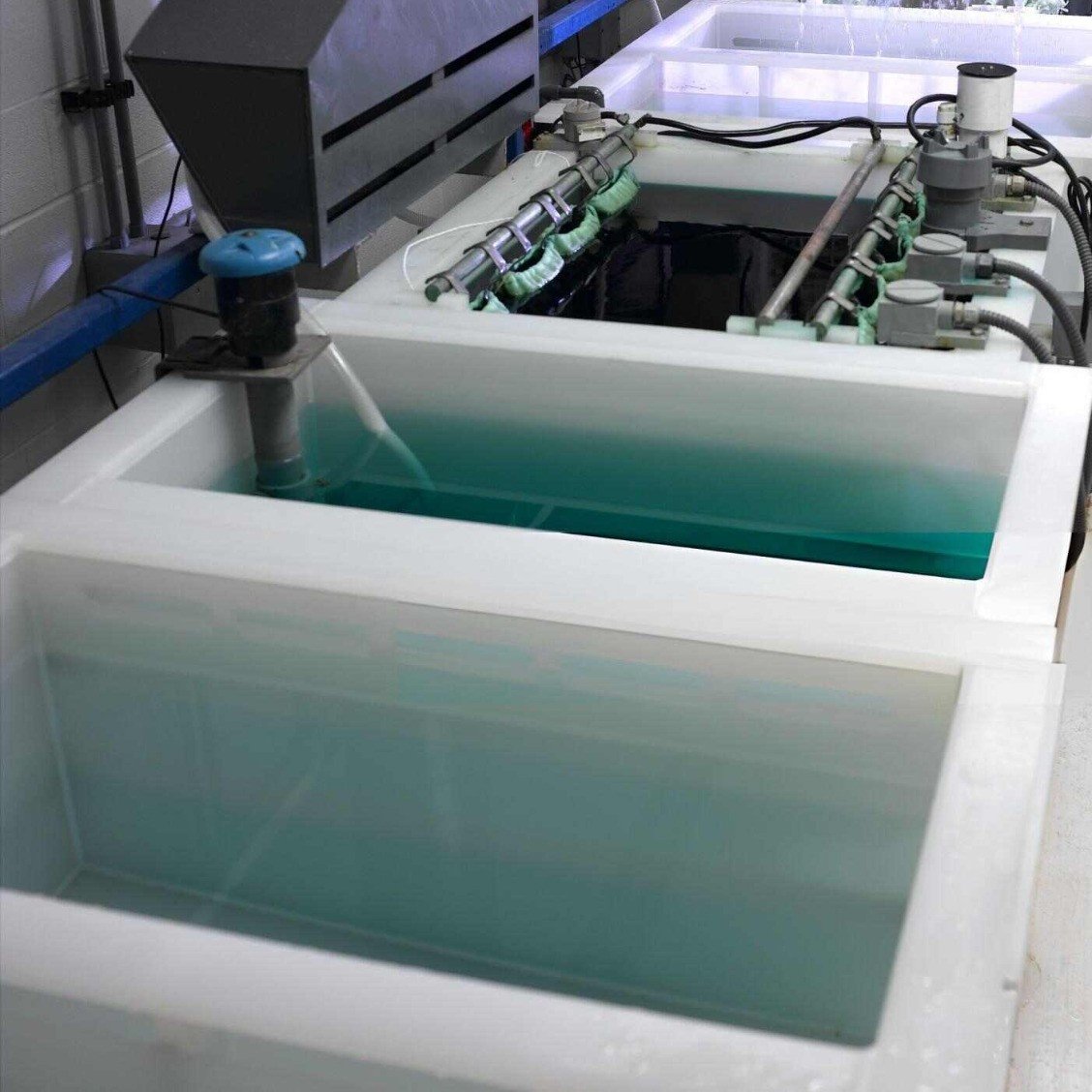

At ASK Enterprises, we take pride in being a leading Chemical Process Tank manufacturer in Ahmedabad, Gujarat, India. Our specialization lies in designing and supplying FRP 7 Tank Process Tanks, engineered to deliver maximum performance, chemical resistance, and durability for diverse industrial applications. With years of expertise, we have become a trusted FRP Process Tank supplier for industries involved in surface treatment, electroplating, chemical processing, and water treatment.

What are FRP 7 Tank Process Tanks?

A 7 Tank Process Tank setup is widely used in surface pre-treatment lines, particularly in electroplating and powder coating industries. The system generally consists of multiple tanks (usually 7 or more), each designed for a specific stage of the treatment process such as degreasing, pickling, phosphating, passivation, rinsing, and other chemical baths.

Our FRP 7 Tank Process Tanks are made from premium-grade Fiber Reinforced Plastic (FRP), which makes them lightweight yet extremely strong, non-corrosive, and resistant to a wide range of acids, alkalis, and solvents.

Features & Benefits of FRP Process Tanks

High Chemical Resistance

Withstand aggressive acids and alkalis used in plating and treatment processes.

Non-Corrosive & Leak-Proof

Prevents leakage and corrosion, ensuring safety and reliability.

Custom-Built Design

Available in various shapes, sizes, and capacities as per client requirements.

Durable & Long-Lasting

FRP construction ensures a longer lifespan compared to MS or RCC tanks.

Lightweight yet Strong

Easy to install and move without compromising strength.

Heat Resistance

Suitable for hot and cold chemical applications.

Applications of FRP 7 Tank Process Tanks

Our FRP Process Tanks are widely used across multiple industries for chemical handling, storage, and treatment applications:

Surface Treatment Tank

Used in industries for degreasing, pickling, phosphating, and passivation processes.

Electroplating Tank

Ideal for nickel plating, chrome plating, zinc plating, anodizing, and other electro-deposition processes.

Chemical Processing Tank

Designed for safe handling of corrosive chemicals in chemical and pharmaceutical industries.

Water Treatment Tank

Used in effluent treatment plants (ETP), reverse osmosis (RO) plants, and wastewater recycling systems.

Industries We Serve

- Automotive & Engineering Industries

- Electroplating & Anodizing Plants

- Powder Coating & Paint Pre-Treatment Units

- Chemical & Pharmaceutical Companies

- Water Treatment & Effluent Treatment Plants

Why ASK Enterprises for FRP 7 Tank Process Tanks?

- Expertise as a Chemical Process Tank manufacturer with proven industry experience.

- Advanced technology and in-house manufacturing facilities for quality assurance.

- Customization available for all types of FRP Surface Treatment Tanks, Electroplating Tanks, Chemical Processing Tanks, and Water Treatment Tanks.

- Commitment to delivering reliable, durable, and cost-effective solutions.

- Dedicated after-sales service and technical support.

If you are looking for robust and long-lasting FRP 7 Tank Process Tanks, ASK Enterprises is your one-stop solution. From surface treatment tanks to electroplating tanks, from chemical processing tanks to water treatment tanks, we provide complete solutions designed to meet your industrial requirements with precision and efficiency.

Enhance your industrial processes with our top-of-the-line FRP 7 Tank Process Plant Tanks

Contact ASK Enterprises today to get a customized solution for your industrial applications